Results 1 to 15 of 23

-

5 July 2016, 17:37 #1

Ruger SR556C at 10,000 Rounds. A Photo Essay.

At long last, I have finally reached the 10,000 round mark with my Ruger SR556C piston driven carbine. This has taken me quite awhile (much longer than anticipated) but I finally did it.

The rifle was purchased new when this model was first released back in 2010. I shot it regularly after I bought it and it took me about a year to get past the initial 5,000 rounds.

I cleaned and maintained the gun on a routine basis for the first 5,000 rounds. It was cleaned and oiled after every major range session and kept fairly wet between cleanings. After the initial 5,000 rounds, I gave the gun a more detailed cleaning and started a thread called "Ruger SR556C at 5,000 rounds - A photo essay." The thread was posted here to show interested parties what the gun looked like after the 5,000 rounds and can be seen here: http://www.weaponevolution.com/forum...-A-Photo-Essay

As can be seen from the original thread, the gun looked pretty good internally and I noted nothing alarming at that time.

Once I had the carbine cleaned and oiled, I decided to continue shooting it but without any routine cleaning. I still added oil to the bolt and carrier when things got a little dry but there wasn't any sort of set plan or schedule. I just added a few drops of whatever oil was handy when I noticed things were getting a little "raspy."

The gun has been used for pretty much every legal purpose at this point. I've shot it in 3gun competitions, various carbine classes and used the upper on a select-fire lower. I've shot slow fire for group and I've shot it fast in range drills. I've gotten it plenty hot and plenty dirty. Still, I never really abused the gun by intentionally throwing it in the dirt or mud or anything like that but I've not babied it, either.

As noted in the 5,000 round thread, the carbine has proven itself to be reliable with brass cased ammo but has given me some issues with cheap steel cased Russian ammo. Silver Bear and Wolf will leave a case stuck in the chamber almost religiously. Interestingly, Hornady's steel cased training ammo works fine as does 75gr WOLF and the old Golden Tiger 56gr stuff. I recently had a bolt override malfunction with an old Sanchez GI mag using Federal Fusion, but it only happened once and I reused that same mag afterward with no other issues.

The carbine has been used mostly on the #2 (middle) gas setting but I did notice that the gun was starting to eject to about the 2:30 or 3:00 position, so I turned the regulator to the #1 (small) setting. This worked most of the time but the gun would occasionally short stroke--especially when fired in unconventional prone or any position that didn't place my shoulder squarely behind the stock--so I switched it back to the #2 setting. Had I not messed with the gas setting at all, I doubt I would have ever had any issue.

Anyway, without further ado, here are the photos.

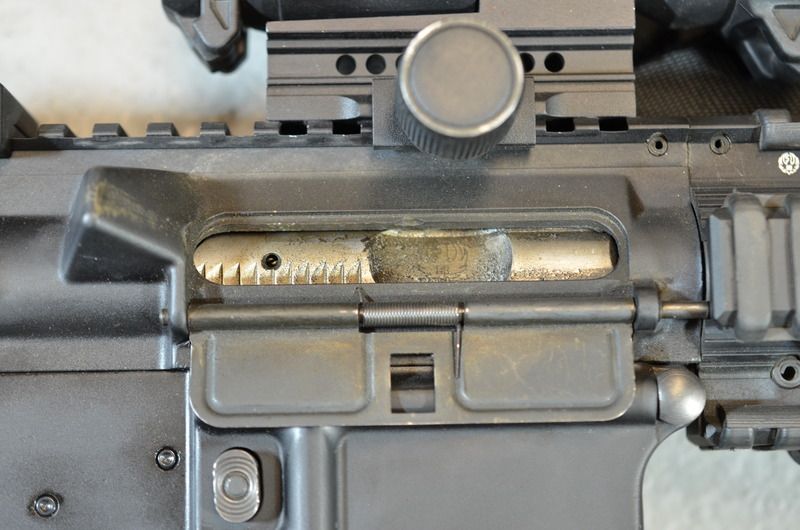

Up first are some general photos of the rifle in the dirty condition:

Note that the dust cover detent is gone. It had been loose on the dust cover for awhile but finally gave up the ghost at about 8,500 rounds.

Finish is worn off the face of the Geissele trigger. This has been in the rifle pretty much since Day One.

Finish worn off the face of the mag release button.

Note the finish wear on the bottom of the bolt catch.

Gas erosion "flash cuts" inside the flash hider. This is common on AR15 birdcage flash hiders.

And now some photos of the forend and gas parts.

Note the purplish hue from carbon fouling along the length of the forend.

This is a difficult area to photograph but there are two distinct little bumps of carbon on top of the barrel underneath the gas block. The Ruger vents gas underneath the block onto the top of the barrel. The little bumps aren't as big as I've seen them and it is my belief that, once they get to a certain point, the vented gas actually blows away anything above a certain height/size.

Note the gas leakage around the gas regulator.

And now some pictures of the disassembled gas system.

Note the fouling/leakage around the gas regulator. The regulator was difficult to remove. I had to stick a small punch through the adjustment/takedown hole and then tap the regulator out with a small hammer. Once the regulator was out, the piston dumped out easily. This surprised me. I assumed the piston would also be hard to remove.

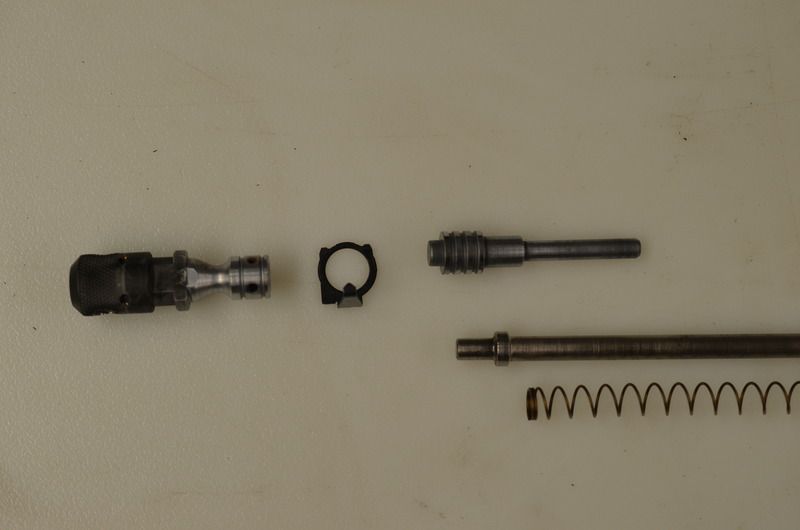

Piston parts removed from the gas block.

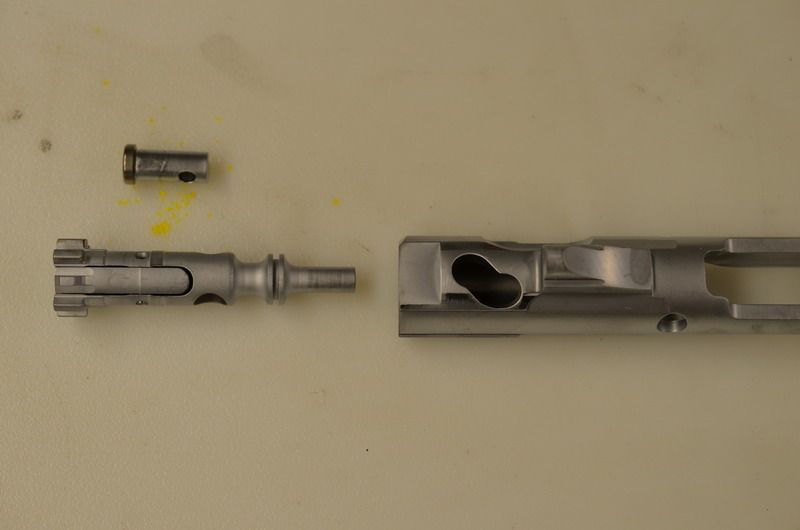

Bolt and carrier parts.

Note how clean the tail of the bolt is where it was "sealed" inside the carrier.

Debris on the carrier. This was mostly localized to the front end of the carrier. Much of this is accumulated oil/lube.

Tip of the firing pin is flat. The focus is off here so it looks flatter than it actually was. Another fairly common sight on well-used AR's.

Barrel extension in bad need of a shave.

Inside the upper.

Receiver bridge on the upper receiver. Note the slight wear caused by contact from the bolt carrier.

The bolt and extractor.

Now the gas block removed from the barrel. Not something covered in the owner's manual. Attempt at your own risk!

Barrel with forend removed. Note flutes to reduce weight.

Barrel nut and piston transfer rod bushing.

Transfer rod and spring removed from forend.

Inside the lower.

Note the lack of any scuffing or finish wear from "carrier tilt."

Parts after cleaning.

Note the slight wear on the shaft of the POF roller cam pin. This is not a stock Ruger part but has been inside the gun pretty much since the get-go.

Bolt parts ready for re-assembly.

Firing pin retainer.

Gas parts ready to go back into the carbine.

Barrel extension after some work with a GI chamber brush and a small screwdriver.

Assembled barrel and forend. No more fuzzy bumps under the gas block.

Wear to the lower receiver bridge from charging handle.

Wear and "cam pin drag" inside the upper receiver.

And the carbine cleaned and assembled. Ready for the next 5,000!

Next up will be to get the gun out to the 100yd range and put it on paper with a few different brands/types of ammo. It has always been a solid 2MOA shooter and I'm curious to see how it shoots now that it has 10,000 rounds down the pipe.

Total parts replaced:

Firing pin--tip flattened on original

Firing pin retainer--original was slightly bent and misshapen

Ejection port cover--broken

Extractor spring--precautionary measure

Magazine release--precautionary measure. The original was working fine but I noticed the shaft was slightly loose on the bar that interfaces with the magazine.

There you have it. The whole event was fairly anticlimactic. Thanks for looking!Last edited by usbp379; 6 July 2016 at 06:40.

-

5 July 2016, 17:56 #2

Absolutely outstanding work and review. Loved the entire read.

-One Nation, Under God

-"The bad news is time flies. The good news is you're the pilot." ~ Michael Althsuler

-

5 July 2016, 18:12 #3

Great review. She cleans up pretty nice. Besides the dust cover, were there any parts that seemed like they might need to be replaced after this last cleaning?

-

5 July 2016, 19:01 #4

Excellent review. Thoroughly enjoyed and appreciated that! Thank you!!

-

6 July 2016, 01:38 #5

Total parts replaced:

Firing pin--tip flattened on original

Firing pin retainer--original was slightly bent and misshapen

Ejection port cover--broken

Extractor spring--precautionary measure

Magazine release--precautionary measure. The original was working fine but I noticed the shaft was slightly loose on the bar that interfaces with the magazine.

Things to monitor:

Buffer and spring--The original is still 10.5" long but I might replace it. Maybe now is a good time to test out the new spring and buffer from Geissele?

Trigger components--I'm not having any issues but I will contact Geissele and see if they recommend anything regarding wear and tear.

Extractor--Original is still working fine and leave slight scratches when drug across my wrist.

Bolt--Lugs have some very slight signs of peening on the backs of the lugs.

Cam pin--The shaft on the pin is showing some flattening/deformation.

The roller cam pin was installed back shortly after POF started selling them as an "end" to cam pin drag. As can be seen from the photos, the cam pin doesn't seem to work. Or could it be that the interior of the upper would look substantially worse without the roller?Last edited by usbp379; 6 July 2016 at 01:45.

-

6 July 2016, 06:59 #6

-

6 July 2016, 10:46 #7

Very nice, thanks for sharing. I'm always amazed when someone does this sort of thing, mostly because I'm thinking ... 10K rounds * $.30/rd minimum ... that's a lotta cheese

-

6 July 2016, 10:59 #8

Awesome. Look forward to the rest.

I've wanted an SR556 since they were released. Friend has one and loves it.Ground Defense 1, Blade Defense 1, Defensive Pistol 1 & 2, Aliance Shoot House, When Things Go Bad, YSINTG, Carbine 1, DART Medical, NRA Range Safety Officer

david@damagephotos.com

Damage Photos on Facebook

@damage_photos on Instagram

Use DAMAGE15 to save 15% at Third Pin Threads

Save 10% "JOINORDIE" http://cmttac.com/

-

7 July 2016, 01:55 #9

Hence my desire to try and run the gun with the cheap Russian stuff.

Much of the 10k has been reloads with some factory stuff mixed in for good measure. I have been using WC844 whenever I can find it in decent quantities. Otherwise the hazmat fee outweighs the cheap price.

-

7 July 2016, 02:00 #10

I like the SR, as can be gathered from all the time I spent with this one. I think Ruger's piston system is solid and will probably run as well as anything else on the market.

They've recently discontinued the SR556 variants and now only make one model--the SR556TD Takedown model. I don't have anything negative to say about the takedown gun per se but it is fairly expensive. And I don't know how many shooters really want a QD barrel.

Regardless, I would have liked to have seen Ruger produce the SR556E. That was the "budget" gun and could be found for under a Grand. I think it was a best buy in the piston market.

-

7 July 2016, 04:43 #11

Caught your follow-up on Arfcom, but again, thank you for your report. I have the SR-556E, and I would agree. I don't know why they wouldn't at least keep that model in the lineup. The takedown model seems a bit strange, and I'd be curious to see sales numbers on it. I'm at a bit over 3,000 rounds in my E, but it's been flawless, and surprisingly accurate. While I've had no issues feeding steel case on occasion, the primary diet has been my own reloads of H335 and a 55gr SP.

Again, thanks for this glimpse into my future!

"There is always a well-known solution to every human problem--neat, plausible, and wrong." - H.L. Mencken

"There is always a well-known solution to every human problem--neat, plausible, and wrong." - H.L. Mencken

-

7 July 2016, 04:58 #12

Yeah this project took way longer than I had anticipated. No real reason for it other than I have been distracted by other shiny objects. Notably an infatuation with 300BLK.

One nice side benefit of the new 556 Takedown is the ability to quickly and easily change the platform over to Blackout. As I foresee it I will never swap my TD back and forth but will leave that gun configured and setup in 300.

Maybe that should be my next project. Long term suppressed testing of Ruger's piston in 300BLK.

-

7 July 2016, 05:27 #13

I would like to see it and read your thoughts on 300 BLK. I love the 147 grain round for general plinking around the farm, but I sure wish the military would contract it so prices would go down!!

There's no "Team" in F**K YOU!

-

7 July 2016, 13:32 #14

Here is a short YouTube video a buddy took for me using his bore scope. Note what looks like charcoal. That used to be rifling!

I have a couple still photos of the throat and gas port on my 556C and another Ruger with less than 200 rounds through it. I'll get them hosted and posted shortly.

Last edited by usbp379; 7 July 2016 at 16:56.

-

7 July 2016, 17:09 #15

Here are some gas port comparison photos.

First up is a new(er) SR556 16" barrel that has less than 150 rounds through it.

Leading and trailing edges of the gas port. Note only slight deformation/discoloration so far.

Now the 556C. The leading edge looks about the same (maybe a little worse) but there's a significant difference on the other side.

Reply With Quote

Reply With Quote